Nitro-Foam Inerting

Nitro-foam inerting is an innovative method developed for the inserting of fuel tanks in lieu of water filling.

As petrol tanks must be made safe prior to opening them up, this method was designed to positively vent explosive vapours from the tanks in a controlled and safe manner.

This type of inerting for underground petroleum tanks can be advantageous when rendering tanks safe for:

- Temporary inerting prior to cleaning and gas-freeing

- Breaking down manhole chambers and exposure of tank tops

- Removal of manlids and associated pipework.

Advantages of Nitro-Foam Inerting

Creating foam filled tanks is cheaper than water filling and subsequent water disposal by tanker. The nitrogen filled bubbles force out fuel vapour and then dissolve away to virtually nothing.

It also saves time, with only one operation instead of two, and avoids delays while waiting for tankers.

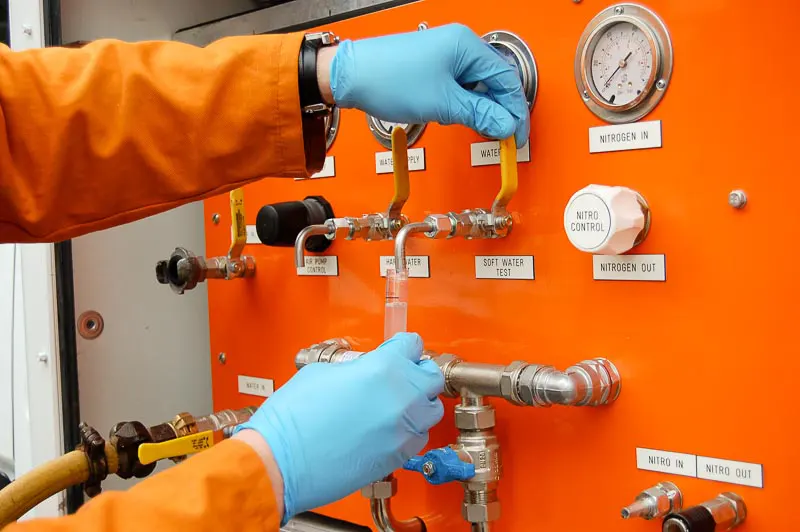

Building on our 20-plus years of experience using Nitro-foam, we have developed and improved our own self contained inerter, which keeps the foam consistent, regardless of local mixing water quality.

The main part to the equipment does not even need unloading from our vehicle to operate.

What is Nitro-Foam Inerting, and why is it used for fuel tanks?

Nitro-Foam Inerting is an innovative method used to make fuel tanks safe, primarily for petrol tanks. It serves the crucial purpose of venting explosive vapours from these tanks in a controlled and safe manner. This method is essential when preparing to open a fuel tank for maintenance or cleaning, ensuring the safety of personnel and preventing potential hazards associated with explosive vapours.

In what situations is Nitro-Foam Inerting advantageous for underground petroleum tanks?

Nitro-Foam Inerting offers advantages in various scenarios related to underground petroleum tanks, including:

1. Temporary inerting before cleaning and gas-freeing.

2. Breaking down manhole chambers and exposing tank tops.

3. Removal of manlids and associated pipework.

What are the advantages of using Nitro-Foam Inerting over traditional methods like water filling?

Here are several advantages of using Nitro-Foam Inerting over traditional methods like water filling:

Cost-Effective: Nitro-Foam inerting is more cost-effective than water filling and subsequent water disposal by tanker. The nitrogen-filled bubbles effectively displace fuel vapour and then dissolve away, minimising waste.

Time-Saving: Nitro-Foam Inerting reduces the process to a single operation, eliminating the need for two separate steps. This efficiency helps prevent delays while waiting for tankers.

Consistency: DP Tanks has developed its own self-contained inerter, ensuring consistent foam quality regardless of local mixing water quality. This innovation enhances the reliability of the Nitro-Foam Inerting process.

Convenient Operation: The equipment required for Nitro-Foam Inerting does not even need to be unloaded from our vehicle to operate, streamlining the process for maximum convenience.

Nitro-Foam Inerting is a reliable and efficient method for ensuring the safety and proper maintenance of fuel tanks.